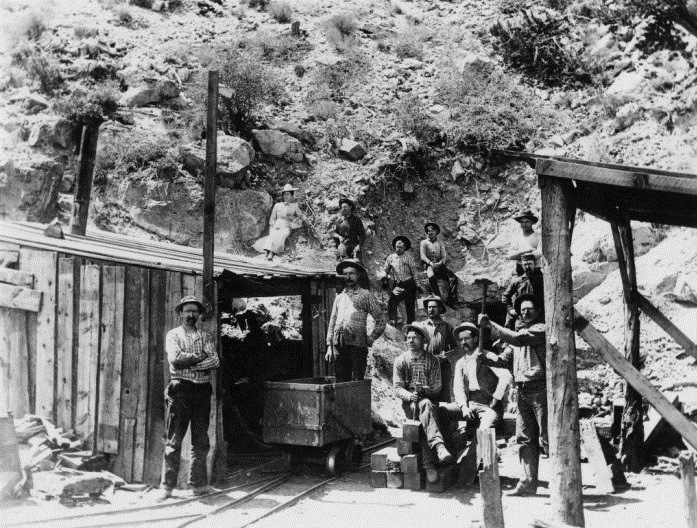

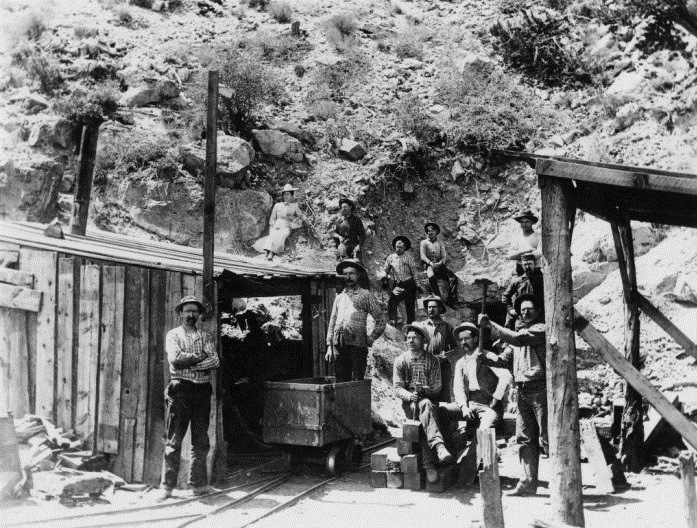

WASHINGTON COUNTY HISTORICAL SOCIETY (Washington County, Utah)

THE APEX MINE

by James E. Kemple

It was only natural that I accompanied my father, John Raymond Kemple, to several of the mines where he worked. There was the Yellow Pine Mine, Chiquita Mine, and the Anchor mine near Goodsprings, Nevada. Also the Black Warrior, and the Apex mines near St. George, Utah. At a very early age, I recall going to the mines at Easter time and finding Easter eggs around the waste dumps. Of course, mother had hidden them for our hunt.

The Chiquita was a gold mine, and since gold was not essential to the WWII war effort the government ordered it closed and told the miners to find work extracting more useful metals. This action precipitated the Kemple family move to St. George.

Father leased the Apex Mine in the early 1940's. I believe Emerald Cox of St. George was the owner. I was about 10 years old.

Of the several mines I went in with my father, the Apex was the best example of a well equipped and operational mine that I can remember. The main tunnel entrance to the mine was located about halfway up the side of the mountain. There were several buildings near the top of the waste dump. One was a small house that could be occupied by the mine manager. There was a bunkhouse that was used by the mine crew when they stayed at the mine for long periods of time. The building to the left of the main entrance was the blacksmith shop and the compressor room. A large air compressor supplied the workers deep inside with the air pressure they needed to run the drilling jackhammers and fresh air for breathing. And just to the right of the main entrance was an equipment room with an array of battery operated lights, and carbide lanterns which the miners wore on their hard hats while in the mine.

After being outfitted with a hard hat and a carbide lantern from the equipment shed, we entered the tunnel. The main entry tunnel went straight back into the mountain for about 200 feet and opened up into a large room-like cavern. The main shaft was in the center with the hoist motor and control to the right. The cage (lift or hoist) was positioned over the shaft and traveled up and down connected to a large cable wound around a pulley at the hoist motor. The miners would ride down on the cage to work all day in the depths of the mine. When an ore car was full, it was pushed onto the cage and brought to the surface. My father operated the hoist with signals from the miners who rang a bell attached to a long cord that extended down into the mine.

On this occasion, father and I got on the cage, and one of the miners operated the hoist, lowering us to the bottom of the shaft. After inspecting the area and evaluating the previous days work, we returned to the cage and signaled the hoist operator that there were "men on cage", and gave the ring to return to the surface. While going up and down the shaft I saw several levels where tunnels were created as the miners followed a vein or "showing" of mineral that could be mined.

Inside the mine was like being in a large cave such as Carlsbad Caverns. The temperature was cool and consistent. There were areas where small drips of water oozed from the sides of the tunnels. The miners had positioned a barrel behind the hoist area to collect the water they used for drinking. I collected several ore specimens which contain high grade copper. I still have those specimens, along with 2 carbide lanterns, on display in my home.

The rest of the day was spent watching my father operate the hoist, and pushing the ore cars out of the tunnel. At age 10, I wasn't strong enough to dump the cars, but my father helped me out. The ore was taken by truck to the railroad at Cedar City and shipped to the smelter. At the end of the day, we came out of the mine and waited to hear the blasts from the dynamite that had been placed in the shaft and tunnels. The shots (blasts) were carefully counted to make sure there were no duds that might explode when the shaft was re-entered. The miners would return the next day to remove the ore that had been blasted loose from the face of the tunnel, and to drill and place new shots that would be fired at the end of that day.

The Apex mine operated intermittently from 1884 to 1962. Over 7000 metric tons of copper, 180,000 troy ounces of silver, and small amounts of gold and lead were taken from the mine. The mine was re-opened in 1985 for gallium and germanium.

WCHS-01356 Apex Mine Entrance (date unknown, but believed to be late 1800's)